The new ISO Circular Economy 59000 series of standards is a game-changer for businesses transitioning from a linear to a circular economy. These standards provide the framework, tools and business procedures necessary to enact and measure the circular economy.

On May 22, 2024, The International Organization for Standardization (ISO) released the hotly anticipated set of three new standards for implementing and measuring the Circular Economy (CE). There will be more to come, but these first three are the foundational tools for enacting business circularity.

I don’t think I’m the only one who got very excited to see the contents of this first set of global circular economy standards. I was particularly inspired by the focus on systems thinking and design as key aspects of enacting CE, as these have been two features of sustainability that I have been promoting and teaching through the UnSchool for over a decade.

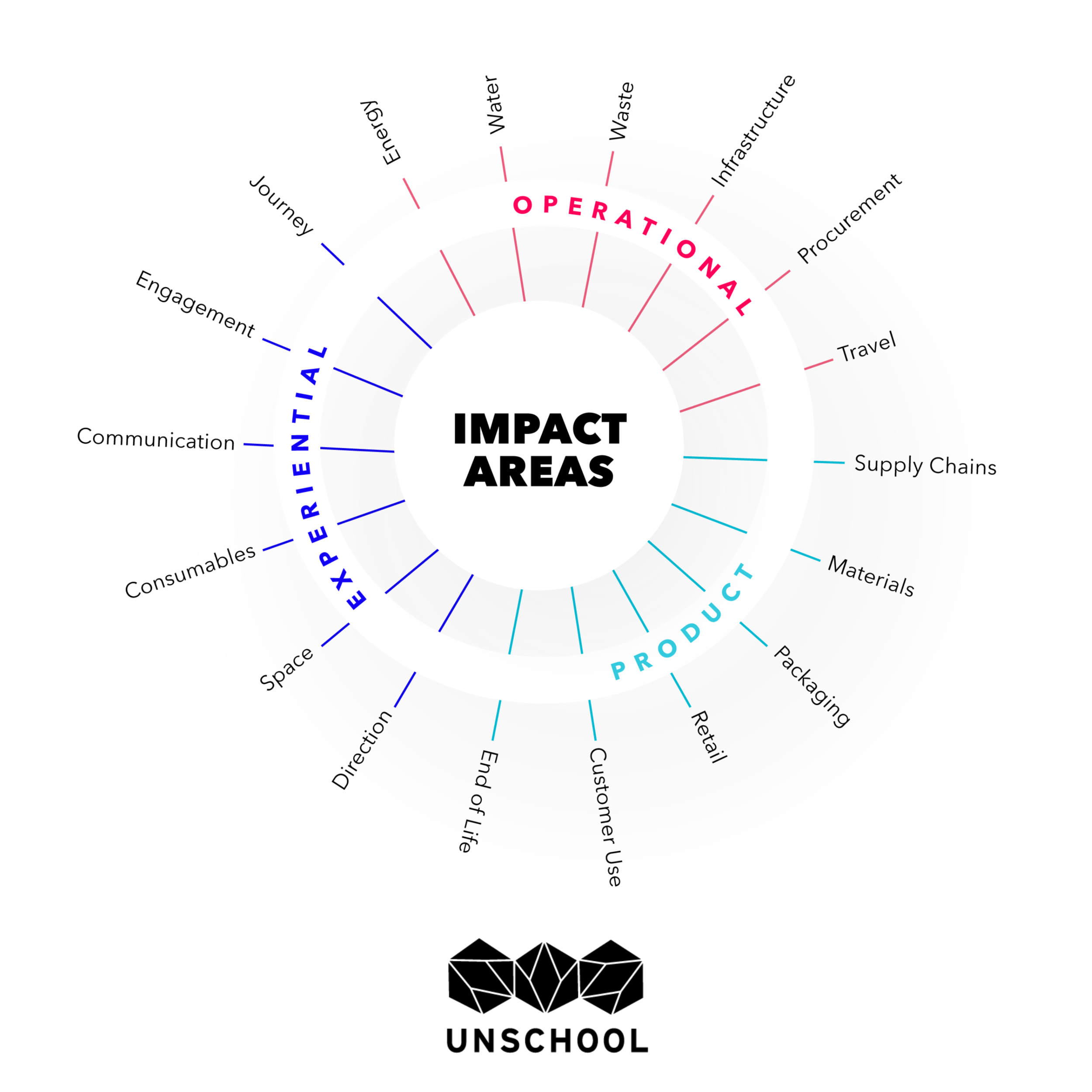

For those of us working to advance a circular and sustainable future, it’s been a very busy time, with lots of new regulations, especially in the European Union (EU), such as the new Ecodesign for Sustainable Products Regulation, and a massive increase in engagement and uptake by companies. So I dedicated the last couple of months to diving deep into the standards, synthesizing the key features and processes outlined within them in order to develop new graphics and put together this article as a detailed quick guide of the circular economy ISO standards.

We need companies to start activating these and for sustainability professionals to be well-versed in their features to support the transition. So, alongside this summary article, we have included more detailed content in our new Level 3 Circular Futures online training program, and I will be running a 2-week live online training in November.

About the new ISO Circular Economy Standards

The three new ISO Circular Economy standards are:

These new standards are a critical part of the maturation of the Circular Economy, as we now have universal frameworks for defining, measuring, reporting and enacting circular economy principles in business. Before these, businesses had to muddle their way through different options for validating CE initiatives. There have been significant contributions to this in the past, such as the Circular Transition Indicators (CTI) from the World Business Council for Sustainable Development (WBCSD), the Global Reporting Initiative (GRI) Standards, Circulytics by the Ellen MacArthur Foundation and the International Sustainability Standards Board (ISSB). Still, many have also resorted to developing their own assessments and reporting methods, which came with a lack of rigor and transparency and often resulted in a non-science-based approach to CE.

What’s critical with any sustainability initiative is that it’s based on solid impact assessment methods and that data is collected throughout the transformation process in order to make measurable and quantifiable improvements. Life Cycle Assessments (LCAs) are the best-practice method for products and services (mentioned throughout the new CE standards), and companies’ operations and supply chains can be assessed through reputable impact assessment approaches. However, there has generally been a scarcity of clarity on what approaches for enacting CE best fit a business, making it hard to determine if what a company has done is achieving measurable circularity and ensuring that claims made are indeed beneficial for the social, economic and environmental aspects of sustainability (this is also one of the key requirements of the standards).

Now, thanks to these new CE ISO standards (and the several additional ones in development), a uniform approach can be replicated. The guidance laid out in them also enables businesses to truly expand their circular ambitions, adopt a systems thinking foundation and ensure that they measure their impacts whilst aiming for high-level CE solutions.

Like anything that has to be universal, there will be some sacrifices and watering down to allow for widespread adoption. But the fact that we now have these in hand means that we can get to work on expanding the circular economy with clarity over which terms, approaches and methods best advance circularity.

“The ISO 59000 family of standards is intended to harmonize the understanding of the circular economy and to support its implementation and measurement.”

This article provides a detailed summary, but there is a lot more to share. So, I have designed a 2-week live online training program to fully unpack what each entails. I’ve done a lot of the hard work in deciphering and synthesizing these so I can seamlessly share them with interested parties and help advance the knowledge set of sustainability practitioners and business leaders who want to ensure they are at the forefront of the CE standards adoption.

Sign up for the program here >

What Makes the Circular Economy So Critical?

Circular solutions are integral to transforming how we produce goods and services, eliminating waste, stopping excess resource use, regenerating nature and ensuring a sustainable future.

Indeed, the key goals of the circular economy are to eliminate waste, make things last longer, and ensure that all extraction and production processes are regenerative. We can achieve this by designing products and services that prioritize reuse, are intentionally designed to last longer, have multiple lives, and can be easily repaired/recaptured for remanufacturing so as not to pollute nature or negatively impact the systems we need to sustain us all.

In short, the circular economy ensures that we are working within the boundaries of the planet. It is a remedy to the current extractive and exploitative linear economy, which ignores consumption’s negative impacts on the environment. There is a progressive global movement to transition economies from linear to circular, with businesses pioneering new models that adopt this and governments mandating new initiatives and goals that enable CE at scale.

The circular economy is designed to be a positive force on the planet, where all players along a value chain take responsibility for their actions (known as product stewardship or extended producer responsibility). Indeed, through good design and leveraging the many different CE approaches, we can meet human needs in more sustainable ways and shift our relationship with nature so that we value the materials and resources that come from it all whilst removing waste and pollution at scale.

With that in mind, let’s unpack the new ISO circular economy standards and how they’ll be instrumental in organizational sustainability.

A quick note on this guide: I have synthesized the standards to create a reference for those wanting to know more about how they can advance CE in their business. We offer more extensive training on CE via a 3-part program, from introductory to advanced, and strongly advise that anyone who wants to significantly improve their capacity in this space based on a scientific approach consider upskilling through training and purchase a copy of the standards to review the internal details that we can’t share due to copyright.

Overview of the Three ISO Circular Economy Standards

While each standard offers unique standalone guidance, all three essentially work together.

The first one (59004) details six CE principles that form the basis for the other standards; it also creates a universal lexicon by defining key terms and offers a stepped approach to implementing CE. The other two main standards refer back to the concepts and terms defined in 59004.

The second standard (59010) shares how to transition organizations to circular models through guidance on value and network transitions, and the third (59020) details and enables measurable outcomes by providing information on impact assessment methods related to CE.

There are also several connected standards and technical papers that are in development:

ISO 59040: Circular Economy: Product Circularity Data Sheet (provides a framework for organizations to measure and assess circularity)

ISO 59014: Environmental management and circular economy — Sustainability and traceability of secondary materials recovery — Principles and requirements (for certification purposes, provides a general methodology for defining, implementing, operating, monitoring, reviewing, maintaining, and improving Product Circularity Data Sheets when acquiring or supplying products)

ISO TR 59031: Circular Economy –Performance-based approaches (will follow the principles of the ISO 59004)

ISO TR 59032: Circular Economy –Review of business model implementation (provides experience-based information to make the circular economy tangible and concrete through a review of business model implementation)

Together, the suite of ISO 59000 standards provides a framework for assessing, implementing and reporting on CE at different scales and enables companies to employ robust, measurable and transparent CE initiatives. Companies in the European Union will also need to comply with the new Ecodesign Regulation and follow the guidance in the ESRS5 when reporting under the CSRD requirements. Thankfully, there is a lot of crossover between these standards and the new ISO standards.

Let’s take a look at each of the three main standards in more detail.

ISO 59004: Circular economy — Vocabulary, principles and guidance for implementation

This overarching standard introduces six fundamental circular economy principles that are the foundations for all other aspects of the standards:

Additionally, the old R levels are expanded to include more R’s (plus a couple of C’s!): refuse, rethink, circular sourcing, reduce, repair, reuse, refurbish, remanufacture, repurpose, cascade, recycle, recover energy, and re-mine. These are referred to as “resource management actions” and enable the foundational application of CE.

The list provided in ISO 59004 on resource management forms the foundation for all of the standards. We have summarized the list provided into this graphic with our interpretations of the actions on the left.

This standard provides several key recommendations on how to enact CE, including:

Ensuring that considerations are made at the early stages of the design and development of a solution/product so that the designs create the highest CE outcomes for minimizing resource use and waste production, referred to as losses and releases (Check out our Sustainable Design course)

Applying a life cycle approach throughout the design process (We also have a course on life cycle thinking and assessment that you can take here)

Embedding systems thinking as a crucial foundation to CE (in fact, it is listed first in the 6 key CE principles!) I’ve written loads on this topic; Start with 6 Fundamental Concepts of Systems Thinking and take our Systems Thinking course here

Collaborating to improve transparency and identify opportunities to add, retain and recover value, as well as to track and manage resources with stakeholders in the value chain

Understanding and measuring the “stocks and flows” relevant to any activities performed by the organization. Stocks and flows are the inputs and outputs and the way they move through the system. This terminology is from systems dynamics (take my 30 Days of Systems Thinking course to learn more about this).

Optimizing production processes to enable product and resource circulation and to adopt the principle of resource stewardship

There are also specific recommendations for engaging with behavior change and for enacting design for circularity, as well as circular sourcing, circular procurement and process optimization.

Another major part of ISO 59004 is that key circular economy terms are defined.

The terms “value creation model” and “value creation networks” refer to how an organization makes money and adds value to society and the supply chain within which the company exists. Both of these must be transformed if a business is to move from linear to circular, and they are used throughout all the standards.

What the definitions help to demonstrate is just how we are shifting our thinking about key aspects of the circular transformation and the role that business plays in this. Whilst these are all terms used widely in the sustainability movement, the provision of definitions in relation to how they apply to CE helps to provide us all with a foundation to build from.

The body of ISO 59004 dedicates several sections to defining an implementation model, which we have summarized in this process flow diagram below. The implementation model is an overarching approach, and in the next standard (59010), there is a specific process of business CE strategy development.

The appendix of 59004 offers a long list of actions businesses can take to implement CE at scale (we provide a much more detailed exploration of these in our Circular Economy Level 3 course).

These actions are referred back to in the other standards; they form a foundational part of the business strategy and value model that a company develops and assesses as part of its circular transformation.

In summary, ISO 59004 is designed as a functional and foundational starting point, defining the universal CE principles, sharing definitions of key terms in relation to enacting CE and providing guidance for implementing CE. The other two standards refer back to this standard to provide all of the important background information.

“Adherence to ISO 59004 enables organizations to create and share more value within society while ensuring the quality and resilience of ecosystems, ultimately supporting a sustainable future.”

ISO 59010: Circular economy — Guidance on the transition of business models and value networks

This standard is designed to provide clarity on how an organization transitions its business model and operations to the circular economy. It details a business-oriented methodology laid out as guidelines for transforming an organization of any size from linear to circular as an actual actionable business strategy.

The document is laid out across the following key stages of circularization:

Setting goals and boundary

Determining a Circular Economy Strategy

Transitioning the value creation model

Transitioning the value networks

Reviewing and monitoring for continuous improvement

The Circular Business Strategy Framework

ISO 59010 details several stages in a Circular Business Strategy (CBS). This process is summarized in the graphic we produced below, and the recommendation in the standard is that it can be applied to any size business or organization from any industry or region.

As the graphic demonstrates, the first stage for a business is to set clear CE goals before moving on to the next stage, determining a strategy that identifies the opportunities and risks. Then comes the transformation of the value creation model (this is the business model and involves considering all the “R” levels that apply to your business — but the R levels mentioned above are actually called resource management actions) and transformation of the value network (which is your supply chain and the role you play within it) before the final stage, reviewing and monitoring, in which you would connect to the measurement guidelines provided in ISO 59020.

Detailing the CE Transition Process

When defining your CE goals, you need to be specific about what you want to achieve in the transition from linear to circular. For example, this can relate to reducing waste/resource flows, improving regenerative practices or extending product life. This will set you up for effective measurement and ensure you have clear goals that influence the rest of your transition process.

Once the goal(s) are set, the company needs to understand the current value creation model and the value network that it exists within. The best way to do this is to map the system that it exists within and continues to operate within (recommendations for doing this are provided in the standard’s appendix, and we offer courses on how to do this as well. See our Intro to Systems Mapping course at the UnSchool and Circular Futures training).

The standard defines these 9 business model elements that the company needs to reflect and define CE in relation to. We have developed a detailed checklist and worksheet for companies to run through in line with the questions and prompts provided in the standard (available to our Workshop participants).

Next up is setting the boundaries for what you will be addressing when it comes to circularity and then understanding your current performance in reaction to CE.

One important thing to understand about the ISO standards (and something I’m personally VERY happy about) is that it’s based on systems thinking, so many of the approaches and terms from systems dynamics are used to provide the guidelines for moving through a CE business strategy.

In this goal-setting stage, you are not just thinking about what you want to achieve but also establishing what is going on within your business system and the network that your system exists within. The maps you produce should identify how resources come in and out of your system, informing the goals you wish to set. This also sets you up for the measurement and assessment processes outlined in ISO 59020.

Some key terms to understand when doing this:

Business System: The scope in which your business operates and how you define your business as a system.

System Boundary: The framework in which you define a system. This can be a physical boundary, such as a factory site, or an intangible one, such as a cultural practice.

Resource Inflows: These are the resources that flow into your system. They are usually materials and should be identified by their type and whether they are renewable, regenerative, or renewable. For the purpose of measurement in the standards, water and energy are addressed in separate categories, but all other resources that enter your business system are accounted for here.

Resource Outflows: An outflow is what exists in your business system. This will include products produced, waste, byproducts and secondary materials. Everything except water and energy are accounted for in this category.

Activating the Transition: Design for Circularity

Design for Circularity (DfC) is detailed as a significant part of the CE business strategy. It involves a product and service creation approach that ensures all design aspects facilitate the wider CE value creation model.

The standard provides extensive guidance on this, including advancing designs that integrate repair, are easily maintained, allow for refurbishment, and can be remanufactured, upgraded, or reused. These designs minimize resource use and prolong product lifetime.

One of the key goals with DfC is to optimize the number of loops or cycles the product/material goes through to actively avoid waste and reduce material use. DfC is based on a systems perspective. This means that the product is not created in isolation but instead designed within the broader systems context, and the specifics of how it exists in the world, specific locations/cultures, etc., are all taken into account when it is created. I’ve also written a couple of handbooks that cover how to do this. Check out Circular Systems Design and Swivel to Sustainability for practical tips.

The standard specifies the following in relation to DfC’s systems perspective: preventing the use or release of substances that can harm human health and ecosystem resilience; considering the full sustainability aspects throughout the life of the product; and exploring new relationships with customers, suppliers and partners to design a suitable value creation model. This approach takes a full life cycle perspective.

Taking Action: Determining a CE strategy

A CE strategy lays out the goals and approaches that your organization will take to enact CE. This should be based on the six circular economy principles identified in 59004 and developed based on the organization’s purpose, vision, mission, identified gaps and opportunities; its need to reposition within the value chain or the value network; its need to expand its sphere of influence; and its desire to achieve a transition towards a more circular value creation model. Again, the concept of a sphere of influence is something we have been teaching at the UnSchool for a decade, and we have many practical tools for exploring and enacting this, like this 10-day Micro Course, Activating your Agency).

Think about your role within the system you are operating within and the opportunity for you to transition your value network towards full circularity. This will involve resource sharing and stewardship, collaboration, traceability and waste minimization.

From the standards perspective, this is about setting up the framework for long-term sustainability by identifying what is needed to achieve your value proposition now and into the future through CE. Your strategy development needs to include long-term resource availability and impact considerations. There are many suggestions made in the standards and we have created checklists to support ease of engagement (available to our workshop participants).

In summary, ISO 59010 is a detailed look at the steps needed for any sized company to transition its entire business model and value chain from linear to circular. It provides specific guidance on how to do this and focuses on the critical role design plays in achieving CE. All businesses should look at this standard and follow the steps when doing a CE transition.

ISO 59020: Circular economy — Measuring and assessing circularity performance

ISO 59020 is structured to provide specific guidance on how to measure and assess circularity at different regional, organizational, product and inter-organizational levels through methods such as:

Defining the “system in focus” for assessment

Overseeing targets and actions (of reduction, repair, reuse, recycling),

Measuring resource flows (including inflows, outflows, and losses)

Assessing sustainability impacts (in social, environmental, and economic systems)

The standard underscores the importance of data collection and analysis by always considering key indicators of circularity, such as the utilization of resources like materials, energy and water. The standard provides these indicators along with the formulas for measuring and appropriate reporting techniques.

The Assessment Framework

The framework for assessment outlines that initially, a context for the assessment needs to be set (this is the system being measured, the CE goals of the organization and any complementary methods that will be used) and is referred to as the “system in focus”.

The former two standards are referred to as the foundations for setting the goals and context for the assessment.

Then, three stages are progressed through:

Boundary setting (defining the system in focus, timeframe and level of the system)

Circularity data acquisition and measurement (select indicators and measure against these)

Assessment and reporting

We produced this graphic to show the steps and elements of these three stages.

The guidelines specify a process of assessment that starts with defining the organization’s goals and then setting a scope of assessment (a system in focus) and a timeframe for the assessment (referred to as temporal state). This is all in relation to CE and sustainability goals. At all stages, the user group, target audience and interested parties are considered.

Some key terms and concepts outlined in this standard:

Circularity measurement requires data acquisition and methods of obtaining and reporting against indicators, which is what this standard lays out the formulas and methods for.

A circularity indicator is a quantitative or qualitative measure of a circularity aspect. From the perspective of the standard, these include mandatory and optional indicators. Below is a table of the mandatory and optional CE indicators.

Resource flows are measured based on internal and external processes, such as what happens inside your scope of assessment and what is external to that. For example, if you are producing a complex product, there are likely many external impacts and flows that you are not accountable for but are critical to your product.

Resource inflows are measured to quantify four types of content and have to add up to 100%:

Percentage of reused content

Percentage of recycled content

Percentage of virgin, renewable content

Percentage of virgin, non-renewable content

In summary, ISO 59020 is more complex than the others, as it offers a robust explanation of circularity indicators, a measurement process and the assessment criteria for validating and reporting on circularity at different levels, from product to organizational to regional. Anyone working to justify their CE performance needs to understand these methods so they can set up appropriate data acquisition and ensure they have been making decisions in line with preferable CE outcomes.

To purchase the standards from the ISO, go here.

Conclusion

Needless to say, this is a complex and detailed arena, and even with my many years of experience and expertise in CE, I had to invest a considerable amount of time to unpack and synthesize the specifics of each of the standards. Now that I have, I am even more fond of them! They really do offer clarity and the specifics that enable businesses of any shape or size to follow a process of transformation, set up data acquisition systems and report effectively on their CE performance.

I’m excited to get started in helping companies apply these to their business and ensure they have the right thinking tools and systems to deliver high-value CE outcomes. If that sounds like something your organization is up for, reach out and contact me, as I’m looking for some interesting case studies to work on.

If you too want to be ahead of the pack on this, join my 2-week Live Online training this November 8th/12th/15th/19th, 12–2pm EST / 5–7pm UK for the 4 sessions.

Get in touch if you are interested in private training programs to advance your skill set or activate CE within your company.